-40%

LENOX 1972921 4.5" x 7/8" Arbor MetalMax Diamond Edge Metal Cutoff Wheel

$ 9.06

- Description

- Size Guide

Description

Don'tsee what you need?

Call us!

1 pcs

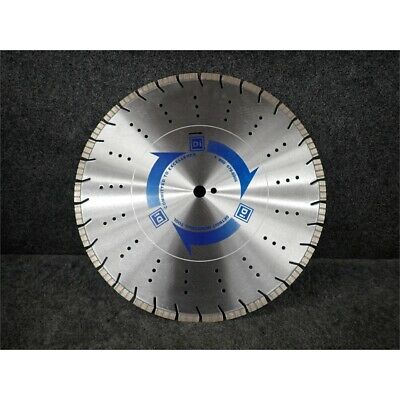

4.5" x 7/8" Arbor MetalMax Diamond Edge Metal Cutoff Wheel

NEW

Brand:

Lenox

Type:

Diamond

Edge

Size:

4.5"

Thickness:

.050"

1,000+ cuts:

MetalMax delivers 1,000 or more cuts with no need for wheel changes. That is 30 times longer life than thin bonded cut-off wheels.*

Long Life:

Advanced diamond technology provides extreme durability in metal cutting applications, leading to increased productivity, reduced downtime, and a lower cost per cut compared to thin bonded cut-off wheels.

Diameter retention:

because LENOX MetalMax is made with diamonds, it doesn't get smaller. The cutting depth stays the same throughout its life, meaning better control, reach and precision.

Less dust residue:

with LENOX MetalMax there is less odor and dust residue as the wheel does not wear down like bonded abrasives. Sparks originate only from the material being cut.

One wheel, multiple materials:

One wheel, multiple materials: MetalMax is recommended for multiple types of metal including steel, sheet metal, stainless steel, rebar, cast iron, aluminum**and non-ferrous metals.

LENOX MetalMax is designed for use in the same power tools as bonded abrasive wheels, at the same RPMs and feed forces. No changes in operating settings are required. Use LENOX MetalMax as you would a bonded abrasive wheel.

*Average performance for 4.5” inch wheel in 1” carbon steel square tube vs thin bonded abrasive cut-off wheels.

**When cutting aluminum, it is recommended to apply cutting wax or other type of saw lubricant to avoid chip welding.

LA Cutting has welding capabilities up to 2” width band.

At this time, LA Cutting is unable to take specific requests on brand types.

You may e-mail us

for a specific quote for your blade size not listed.

More than 20 Years

in the industry with excellent customer service. LA Cutting Products weld center has what you are looking for!

Don't see what you are looking for

contact us and we will send you an updated quote for what you need.

Every blade is

Made To Order

with capabilities up to 2" width! Check out the store below for some more great deals!

LA Cutting Products Store

1/4" Blades

3/8" Blades

1/2" Blades

5/8" Blades

3/4" Blades

1" Blades

Butcher Blades

Machine Care & Maintenance

Tools

Terms and Conditions.

Once a bid has been placed it is a legally binding contract of purchase.

Payment must be received immediately of purchase. However, larger volume customers may contact us for specific terms.

LA Cutting will notify you via e-mail when your goods have been shipped, along with tracking information.

Once you receive your goods, please inspect them for any damage during transit. If all is well, please leave Positive Feedback with 5 star ratings so we are aware that you have received your goods.

Please Note:

to report damage, notify us within 24 hours via e-mail by contacting LA Cutting directlywith your User ID and full details of the problem with a couple of photos.

LA Cutting ships via Federal Express Ground and U.S. Postal Service.

We accept no responsibility for goods delayed due to the services of the carrier.

Goods will be dispatched within 1-2 business days of cleared fund.

Band saw blades are made to order as specified above. Should there be any issues with the blade or shipment, please e-mail LA Cutting Products with your User ID and a description of your concern, along with a couple of photos.

LA Cutting Products guarantees its welds 100%.

Always double check your machines blades specs!

NOTE:

The owner's manual of some woodcutting bandsaw may stipulate that it can cut metal, but woodcutting bandsaws can only cut non-ferrous metals, such as aluminum, brass, copper, etc.

Cutting steel could damage your saw, due to the fact that blade speed on most woodcutting bandsaws (average 800 to 3500 fpm) this is not slow enough (40 to 300 fpm) for cutting ferrous metals (like steel).

Trying to cut steel at woodcutting speeds will ruin the blade due to extreme heat produced due to the speed. Bi-Metal bandsaw blades can cut all types of woods and are especially ideal for hard woods, like oak, maple, walnut or cherry.

Bi-Metal bandsaw blades are also most commonly used for metal cutting, like carbon steels, light alloy steels, mold steels, and tool steels.

Below is a helpful guide to picking the best blade for your needs.

1/4" Blades

General Purpose Cutting ?= 10/14N

Larger Materials = 6H

Tubing = 10/14N

1/2", 3/8" Blades

General Purpose Cutting = 8/12N

?Small Thinner Materials = 10/14N

Larger Materials = 6/10N

Tubing = 8/12N

3/4" Blades

General Purpose Cutting = 8/12N

?Small Thinner Materials = 10/14N

Larger Materials = 6/10N - 5/8N

Tubing = 8/12N - 6/10N

1" Blades

General Purpose Cutting = 5/8N

??Small Thinner Materials = 10/14N

Larger Materials = 4/6H

Tubing = 8/12N - 6/10